Services

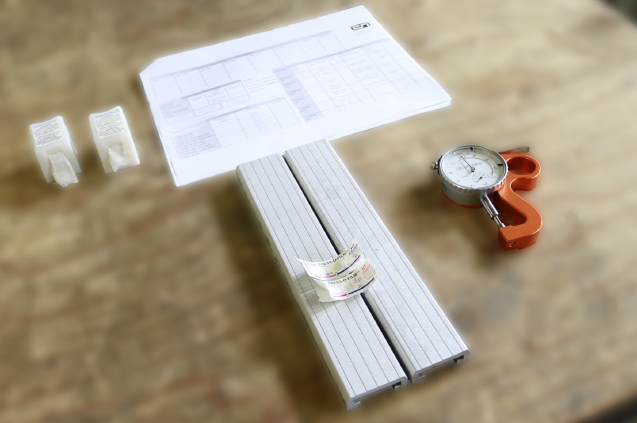

Our finished products are tested statically and dynamically. The presence of our universal testing machine helps us to determine how much load our products are capable to endure. Stringent sampling procedures for destructive testing ensure that our products meet strict quality standards.

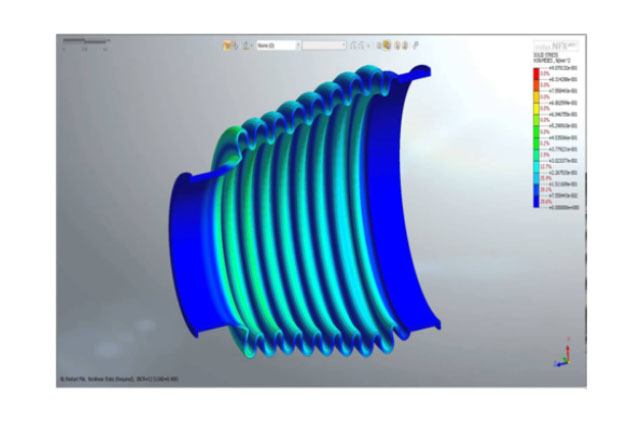

When we are approached to make custom rubber parts for specific applications, we design and test using Finite Element Analysis. With the help of Finite Element Analysis and CAD software, Contact Rubber can predict the stress, fatigue, static and dynamic response of the products we manufacture.

With the advancement of technology and rubber being an irreplaceable commodity for elastic applications, we aim to thrive as a pioneer in this domain to ensure that quality and performance are reflected on our products.

Our finished products are tested statically and dynamically. The presence of our universal testing machine helps us to determine how much load our products are capable to endure. Stringent sampling procedures for destructive testing ensure that our products meet strict quality standards.

When we are approached to make custom rubber parts for specific applications, we design and test using Finite Element Analysis. With the help of Finite Element Analysis and CAD software, Contact Rubber can predict the stress, fatigue, static and dynamic response of the products we manufacture.

With the advancement of technology and rubber being an irreplaceable commodity for elastic applications, we aim to thrive as a pioneer in this domain to ensure that quality and performance are reflected on our products.

Contact Rubber is a leading manufacturer and distributor of rubber molded parts, focusing on custom and customer specified requirements.

Customer First, Customer Always